When it comes to designing a piping system, selecting the right fittings and flanges is essential. Piping fittings are used to connect sections of pipe or other equipment components, while flanges are used to connect pipes and other equipment to each other or to valves or other components. Together, fittings and flanges form the backbone of a piping system, ensuring that it is safe, efficient, and effective in transporting fluids, gases, or other materials.

Types of Piping Fittings

There are many different types of piping fittings, each designed for a specific purpose or function. Some common types of piping fittings include:

Elbows: Used to change the direction of flow in a piping system. Elbows are available in various angles, including 45°, 90°, and 180°.

Tees: Used to connect three pipes at right angles to each other.

Reducers: Used to connect two pipes of different sizes.

Couplings: Used to connect two pipes of the same size.

Unions: Used to connect two pipes together, but with the ability to disconnect them for maintenance or repair.

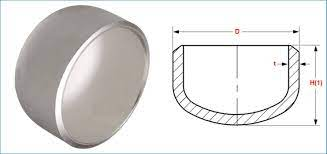

Caps: Used to close off the end of a pipe.

Types of Piping Flanges

Flanges are another critical component of piping systems. Flanges are used to connect pipes and other equipment together, and also to connect piping systems to valves, pumps, or other components. Some common types of piping flanges include:

Weld Neck Flanges: Used for high-pressure and high-temperature applications. These flanges have a long tapered hub and are butt welded to the pipe.

Slip-On Flanges: Used for low-pressure and low-temperature applications. These flanges are slipped over the end of the pipe and then welded in place.

Threaded Flanges: Used for low-pressure and low-temperature applications. These flanges have threads on the inside bore and can be screwed onto the pipe.

Socket Weld Flanges: Used for small diameter high-pressure and high-temperature applications. These flanges have a socket that is welded to the pipe.

Blind Flanges: Used to seal off the end of a pipe or to close off a connection point.

Selecting the Right Fittings and Flanges

When selecting fittings and flanges for a piping system, several factors must be considered. These include the material of construction, the size of the pipe, the pressure and temperature of the fluid being transported, and the specific application requirements. It is essential to choose fittings and flanges that are compatible with the piping system and are rated for the specific conditions and demands of the application.

Conclusion

Piping fittings and flanges are essential components of piping systems, allowing for safe and efficient transportation of fluids, gases, or other materials. Selecting the right fittings and flanges is crucial to ensure that the piping system functions effectively and meets the specific requirements of the application. With the right fittings and flanges, designers can create piping systems that are safe, reliable, and long-lasting.

No comments:

Post a Comment