CHECK VALVE (NON RETURN VALVE-NRV)

SWING CHECK VALVE:

TILTING DISK CHECK VALVE

WAFER TYPE CHECK VALVE

· Face to Face: ANSI B 16.10

DISC CHECK VALVE

The Single Disc Check Valve (Wafer Type Disc Check Valve) consists of four main components: the body, a disc, a star guide and a spring. The Disc check valves are opened by the pressure of fluid and closed through compression spring as soon as flow stops thus preventing reverse flow.

The design of Wafer Design, Sandwich Type Single Disc Spring Loaded Check Valves allows them to be installed between any flanges of different standard and in any position; including vertical pipelines where the fluid flows downwards.

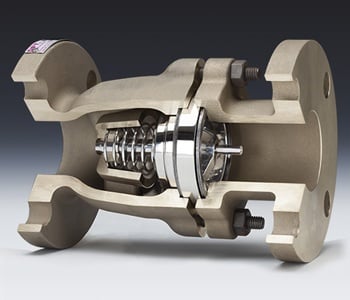

PISTON CHECK VALVE

Piston Check valves are generally used to protect pumps or similar equipment, allowing the flow only in one direction and preventing flow reversal due to back pressure. The piston check valves are designed with globe valve bodies, producing an increased drop pressure in the pipeline. This design provides a tight seal as well as a fast reaction to the closure impulse. Metal seated check valves may not provide drop tight sealing when used in gas system or fluid system with low back flow pressure or fluids containing particles.

· Face to Face: ANSI B 16.10

BALL CHECK VALVE

The ball check valve is one of the few check valves that works well in both water and wastewater applications. Ball check valves are simple in operation and commonly used on small pumps and in low head systems. Consider adding an optional roll-bar to the piping system for safety; ball check valves have the highest tendency to slam due to the ball's high inertia long stroke. When ball check valves encounter high pressures and dynamics, severe slamming may result.

· Face to Face: ANSI B 16.10

DUAL PLATE WAFER CHECK VALVE

The Dual Plate, Wafer Check Valve employs two-spring-loaded plates hinged on a central hinge pin. When the flow decreases, the plates close by the action of torsion spring before flow reversal takes place. All features put together make the Dual Plate Check Valve as the most efficient & versatile design. It is also referred to as SILENT CHECK VALVE. It is much easier to install between standard gaskets and line flanges, and therefore is more cost effective to install and to maintain. Its design complies with API 594 and API 6D, testing with API 598. It is also called as Butterfly Check Valve.

NON-SLAM CHECK VALVE

It is essential to see the closing characteristic of the valve with the dynamics of the pumping system.

The swing check valve closes abruptly because of gravity, and causes pressure surge resulting in shock waves. These high pressure waves causes sever stress on the piping system. This problem can be minimized by installing a Non-Slam type check valve. Non-Slam check valve do not rely on gravity. As the upstream velocity of the fluid slows the spring assist on the valve start to close the disc. By the time the upstream velocity comes to 0, the disc is completely closed. With the reverse flow eliminated, the force necessary to produce water hammer on either side of the valve are substantially reduced.

Excellent

ReplyDeleteVery well orgnized webpage...

ReplyDeleteThanks for the informations.

Good

ReplyDeleteGOOD

ReplyDeleteGood

ReplyDeleteCLEAR EXPLAIN. GOOD PHOTOS. TAHNKS

ReplyDeletelike this blog,

ReplyDeletethanks,

ReplyDeletefor dual plate wafer check valve need to be careful when install it.. it's can't be connected directly to flange due to it will block the plate

That is great to hear, thank you for reading!

ReplyDeleteGreat post. Thanks for sharing!

ReplyDelete